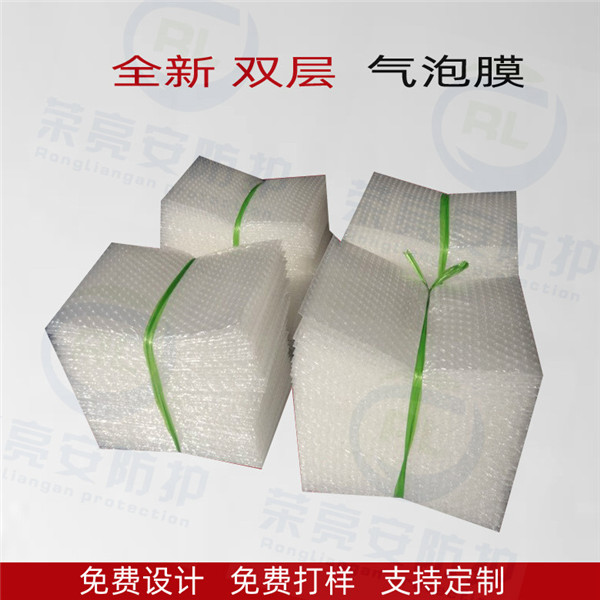

The air bubble bag is mainly made of high-pressure polyethylene bubble film through cutting the film, cutting the film into the required size of the bag, and then the bag is made and processed by a special machine for making air bubble film, a hot-drying and hot-cutting bag making machine, it is mainly used for cushioning packaging of electronic products, plastic products, metal products, ceramic products, glass products and other products that need cushioning protection, logistics and transportation protection. The bubble film is made of high pressure Low-density polyethylene and is a widely used transparent flexible packaging material. The principle is to contain air film to form bubbles to prevent product impact, to ensure that the product shock protection, but also the role of thermal insulation, suitable for all walks of different product packaging or turnover! Because the air cushion membrane middle layer is full of air, so the body is light and elastic, with sound insulation, shock resistance, Abrasion resistance performance, it is waterproof, moisture resistance, pressure resistance, single-side bubble bag is suitable for anti-static bubble roll protection of its own light weight products, double-side bubble bag is suitable for large and heavy packaging. Single, double-sided bubble bags are suitable for all industries of product packaging, such as bag, slice. Single and double side air bubble bags can be equipped with anti-static air bubble bags, and different colors, printing. Can also compound other materials to increase the protection and aesthetic. PAPER BUBBLE BAGS: KRAFT PAPER BUBBLE BAGS, pearlescent membrane bubble bags, aluminized platinum bubble bags, transparent bubble bags (with two or three layers) by material bubble bags: ordinary bubble bags, anti-static bubble bags, conductive static bubble bags.